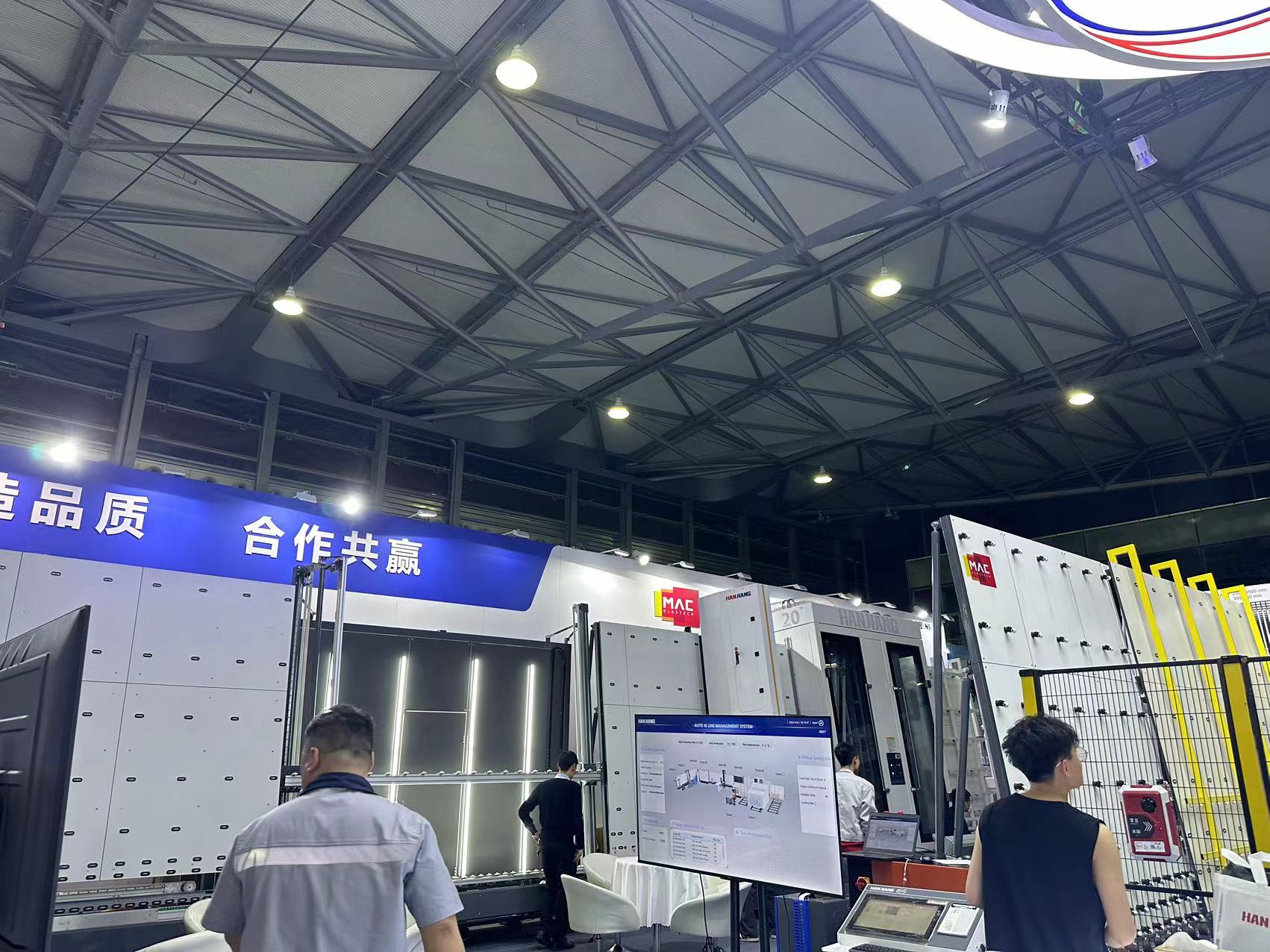

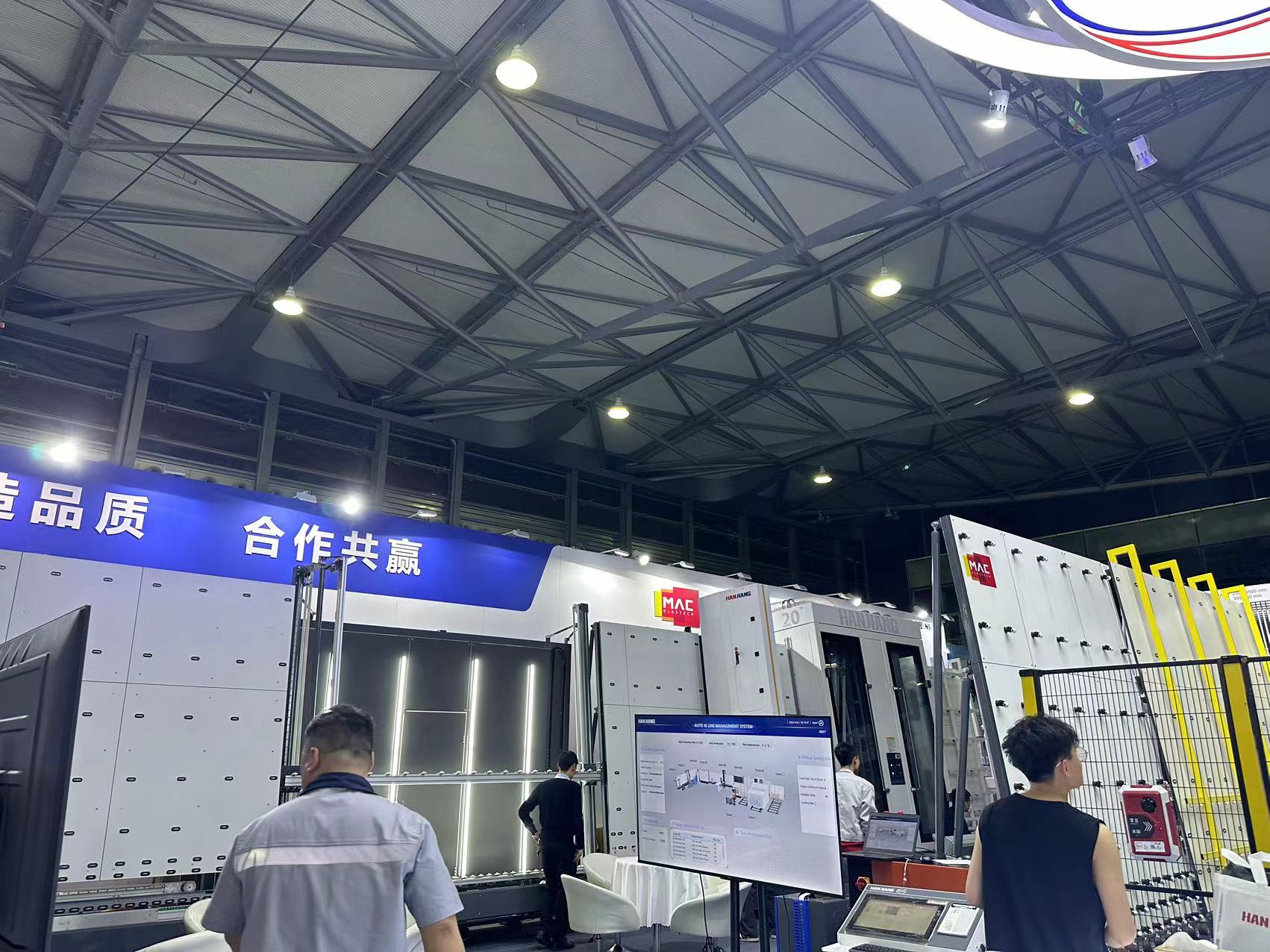

During this exhibition HANJIANG-MAC showed S series vertical sorting system service OMNI INSULATING GLASS LINE.

All the experienced processors find, lot of time will be wasted for paring the glass before INSULATING GLASS production.

HANJIANG-MAC will achieve fully automatic production on pairing and supplying to the INSULATING GLASS line according to the order sequence.

For INSULATING GLASS processing, You may familiar with the following solutions from Hanjiang.

#1 Classic INSULATING GLASS line with other automatic auxiliary machine for basic INSULATING GLASS processing.

#2 When INSULATING GLASS U orders show more variety, we can go for online gas filling line with automatic edge deletion and sealing robot to ensure reputational position in the market.

#3 When we need to process jumbo INSULATING GLASS or more complicated INSULATING GLASS structure triple and 4-side step together, OMNI series will help on better competitiveness in the market.

Even future, traditional Insulating Glass id spacer INSULATING GLASS line can upgrade to warm edge spacer line. integrate with super spacer robot or TPS. Can easily achieve Insulating Glass h automation for all kinds of spacers.

In traditional INSULATING GLASS processing, it is necessary to input order information or adjust mechanical parts to accommodate various factors such as glass thickness, sizes, sealing depth, quantity, spacer width, and whether it's argon or step size.

MES system on INSULATING GLASS line can solve all above headaches completely.

Receiving the entire order information from the customer's upper system. Overseeing all machinery and automatically adjusting to meet all order specifications for processing. Implementing complete automation in coordination with HANJIANG OMNI INSULATING GLASS LINE series. Glass will be fed into the INSULATING GLASS line in a sequential order, with real- time tracking and reporting to avoid manual errors in machine settings

and output.

HANJIANG-MAC will keep to provide intelligent solution for deep glass processing solution.